Circular economy: maximising reclamation of materials

From selective deconstruction to repurposing and recycling materials, our teams strive to optimise the use of raw materials from the initial study phase of their projects and then make environmentally responsible use of them. We therefore prioritise material reclamation procedures, both internally and in partnership with local organisations.

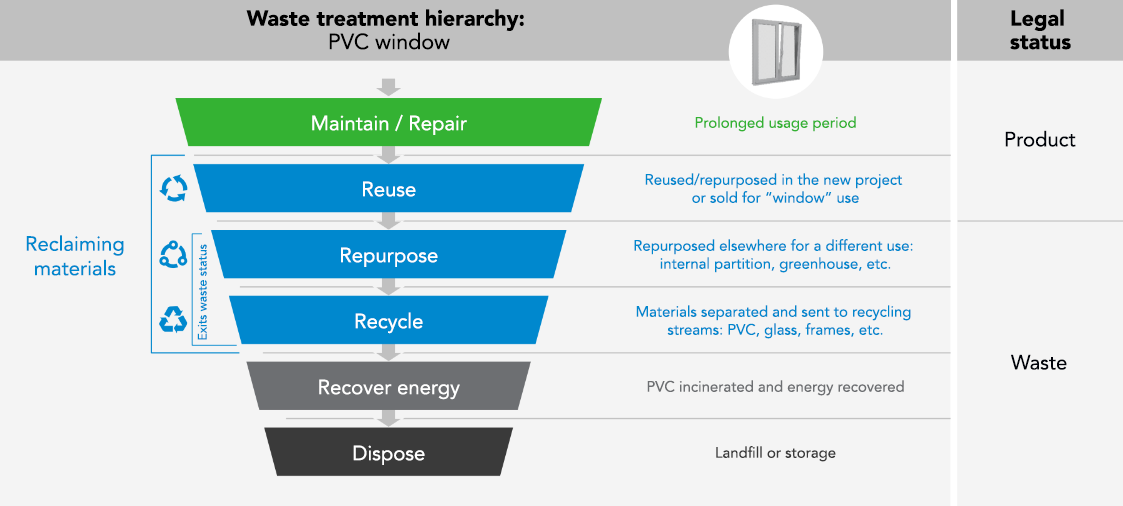

Reclaiming materials: highly regulated but crucial

Environmental regulations lay down a hierarchy of waste treatment methods, essentially an order of priority for waste management defined at European level. The aim of this hierarchy of treatment methods is to encourage the reclamation of waste and thus reduce or even completely avoid the use of virgin raw materials. The best waste is the waste we never produce.

LaVallée: an ecodistrict to showcase our circular economy solutions

In 2018, as part of the future LaVallée ecodistrict in Châtenay-Malabry (Hauts-de-Seine), Eiffage Aménagement installed a large-scale circular economy demonstrator for the selective deconstruction of the former École Centrale.

An initial “resources diagnostic” was completed ahead of the deconstruction phase involving some of the former educational establishment’s buildings. Its aim was to identify the reuse/repurposing potential of interior fittings (luminaires, doors, toilets, handrails, emergency lighting, etc.) to ensure that everything possible was reclaimed. What in the past would have been considered waste to be processed has become a valuable source of materials. Even at the call for tenders stage of the clearance and demolition process, Eiffage Aménagement was encouraging its partners to prioritise the selective deconstruction of the target buildings, in order to maximise the quality of the materials and products recovered. Concrete from the deconstructed buildings was crushed and recycled, with 98% reused on the same site. As a result, the first part of the ecodistrict, handed over in 2022, included up to 30% recycled aggregates in all the concrete for the building superstructures.

RéaVie: reusing materials and creating jobs

Eiffage supports the RéaVie association’s work in Île-de-France. Founded by former construction professionals, the association helps preserve hundreds of products, equipment and materials, and promotes their reuse. For example, RéaVie supported work by the demolition firm Boutté to ensure recovery of the maximum quantity of materials, which include false ceilings, plaster and glass partitions, doors, carpets, and electrical accessories, from the nine-hectare former PSA site in Garenne-Colombes, where an office building dating from 2013 required deconstruction. The project owner had asked the demolition companies to propose a circular economy-based approach. The schedule was altered to deal with the deconstructed building last, so that the preparation phase made it possible to integrate the reuse strategy as fully as possible.

In addition, on the Châtenay ecodistrict project site, an experimental repurposing platform called Solid’R was created. Materials were collected, sorted, repaired and reconditioned, then sold to associations and individuals of limited means. Some materials were also transformed in sewing and woodworking workshops, combining the circular economy and solidarity!

RéaVie: reusing materials and creating jobs

Reuse of materials and upcycling

B3 Ecodesign - Responsible Housing

The circular economy and design can go hand in hand, as proven by the projects delivered by B3 Ecodesign, a company acquired by Eiffage Construction in 2019 that specialises in modular construction using old shipping containers. Its processes are inspired by the automobile industry’s lean manufacturing approach to maintain production in line with demand, eliminating waste.

To do so, B3 Ecodesign uses a process called upcycling, which involves transforming waste materials into higher quality products. Upcycling converts shipping containers into modern designer housing, offices or retail outlets.

This circular economy-inspired construction method offers great flexibility, saves materials and time, and is architecturally pleasing.

B3 Ecodesign - Responsible Housing

Key figures

-

60.3 tonnesof equipment and materials reused on the Airbus industrial workshops project in Toulouse in 2022

-

83%recycling rate for waste held by Eiffage in 2022 (France).

-

2,700 m²of false flooring slabs and 835 m2 of facade stone was repurposed as flooring on the L1ve renovation project.

Materials recycling and carbon storage

“Nothing is lost, [...] everything is transformed” This quotation attributed to the chemist Antoine Lavoisier perfectly reflects Eiffage Route’s philosophy, which places the reclamation of materials at the core of its strategy.

Eiffage business lines are working on multiple disruptive innovations, thanks to the 50-strong team of researchers, engineers and technicians in Eiffage Route’s research centres in Ciry-Salsogne (Aisne department) and in Corbas, near Lyon.

Their objective is to develop competitive business activities based on the reclamation of previously extracted natural resources, and their replacement wherever possible by biosourced products.

Another example is to be found on the Fretin ecosite, near Lille, where RMN (Recyclage des Matériaux du Nord) and PréferNord (Préparation de Ferrailles du Nord) have created a recycling platform. The 14-hectare site contains a section entirely devoted to reclaiming materials from deconstruction (RMN), with another given over to the reclamation of incineration residues, which can be recycled in the steel industry.

Recarbonising old concrete in LaVallée

In order to reduce pressure on mineral resources and offer a CO2 storage solution, Eiffage is testing out a new, innovative method in LaVallée, where it is injecting pressurised CO2 into old concrete from demolition. Against a backdrop of dwindling quarry reserves and an unsustainable rate of sand mining, CO2 sequestration is a promising solution that captures carbon dioxide and greatly increases the recyclability of old aggregate, meaning less new aggregate is needed.

Recarbonisation of concrete